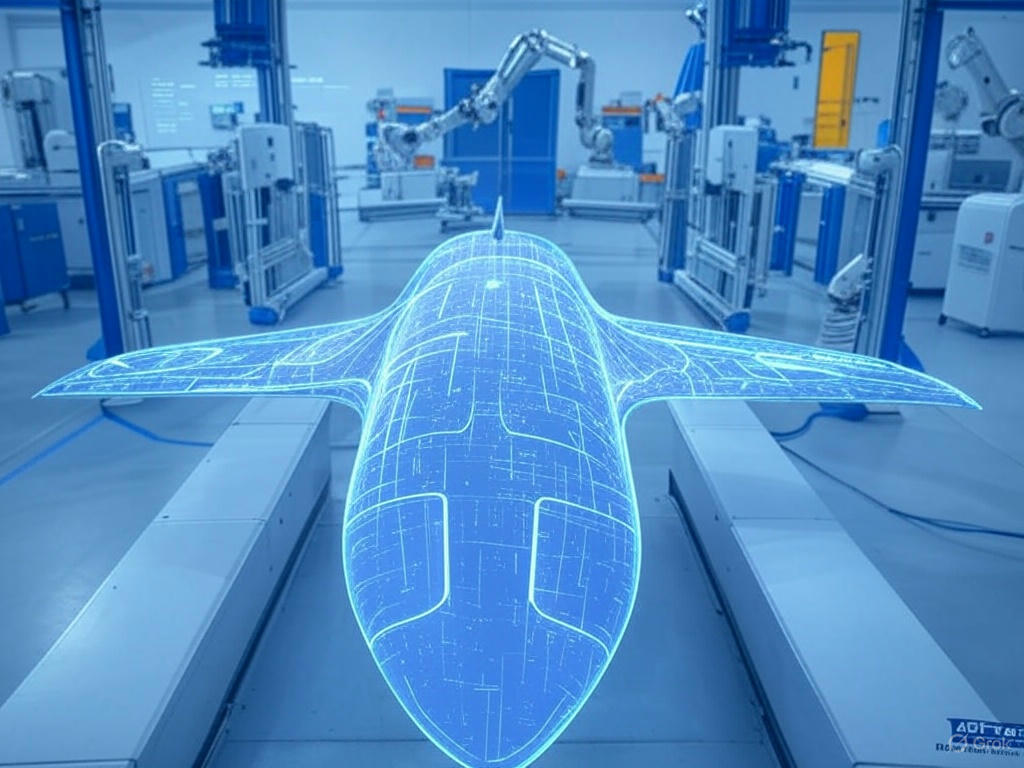

How AI-Powered Quality Control is Saving Aerospace Manufacturers Millions

I’ve been thinking a lot about how aerospace manufacturing is such a high-stakes game—there’s zero room for error when you’re building something that’s going to fly at 30,000 feet. One tiny flaw can cost millions, not to mention the safety risks. That’s where AI-powered quality control comes in, and let me tell you, it’s a lifesaver. At Jet Tech Supplies, we’re helping manufacturers catch defects early with our machine vision software, and the results are pretty jaw-dropping. Here’s how AI is revolutionizing quality control in aerospace and saving companies big bucks along the way.

Why Quality Control is a Big Deal in Aerospace

Let’s be real: in aerospace, perfection isn’t just a goal—it’s a requirement. A single micro-crack in a turbine blade or a misaligned bolt in a wing can lead to catastrophic failure. Plus, scrapping defective parts or reworking them eats up time and money. Traditional inspections, where humans check every inch, are slow and can miss things. That’s why AI is stepping in to take quality control to the next level, and we’re seeing some serious savings as a result.

-

The Stakes: One defective part can cost thousands to replace, plus downtime and delays.

-

Our Take: We’re here to make sure your parts are flawless, without the stress.

Catching Flaws Faster Than Ever

Our AI-powered machine vision software is like having a superhuman inspector on your team. It uses high-res cameras and smart algorithms to scan components at lightning speed—think thousands of parts per hour. It can spot defects as tiny as a hairline crack or a slight misalignment that a human might miss. Rolls-Royce has been using similar tech to inspect their turbine blades, ensuring every piece is perfect. With our software, you’re catching problems before they spiral into costly disasters.

-

Why It’s Awesome: Faster inspections mean you keep production on track.

-

Our Take: It’s like giving your factory x-ray vision, but better.

Cutting Down on Rework and Scrap

Here’s the thing about defects: if you don’t catch them early, you’re either scrapping the part or spending hours fixing it. Both options are expensive. Our software helps you spot issues right at the start of the production line, so you’re not wasting materials or labor on parts that won’t make the cut. One of our clients reduced their scrap rate by 15% after using our system—that’s thousands of pounds saved on materials alone.

-

Why It Saves Money: Less rework and scrap mean lower costs and happier budgets.

-

Our Take: We’re all about getting it right the first time, so you’re not throwing money away.

Ensuring Compliance Without the Headache

Aerospace has some of the strictest regulations out there, and failing to meet them can lead to fines, delays, or even grounded planes. Our AI software doesn’t just spot defects—it logs every inspection, giving you a detailed record to prove compliance with standards like AS9100. It’s like having a digital paper trail that says, “Yep, we nailed it.” That kind of peace of mind is priceless when you’re dealing with audits or certifications.

-

Why It’s a Game-Changer: Compliance becomes a breeze, with no risk of penalties.

-

Our Take: We’ve got your back when it comes to keeping regulators happy.

Scaling Up Without Losing Precision

As production ramps up, maintaining quality can get tricky. More parts mean more chances for something to slip through the cracks. But AI doesn’t get tired or overwhelmed. Our system scales with your needs, inspecting just as thoroughly whether you’re making 100 parts or 10,000. It’s the kind of reliability that lets you grow without worrying about quality taking a hit.

-

Why It Matters: You can take on bigger projects without sacrificing standards.

-

Our Take: We’re here to help you grow confidently, no matter the scale.

Real Savings, Real Impact

Let’s talk numbers. Catching a defect early can save you anywhere from £1,000 to £10,000 per part, depending on the component. Multiply that by hundreds of parts, and you’re looking at millions in savings over a year. Plus, you’re avoiding delays that can cost even more in lost contracts or penalties. Companies like Rolls-Royce and Boeing are already seeing the benefits, and with Jet Tech Supplies, you can too. Our clients have reported up to 20% lower quality control costs since switching to our AI system.

The Future of Quality Control in Aerospace

AI isn’t just a quick fix—it’s the future. We’re already working on next-gen features, like integrating machine vision with predictive analytics to not only spot defects but predict where they’re likely to happen. Imagine knowing exactly which machine needs a tune-up before it starts producing duds. That’s the kind of innovation we’re bringing to the table at Jet Tech Supplies.

Let’s Make Quality Control a Win

Quality control doesn’t have to be a money pit. With AI, it’s an opportunity to save big while keeping your standards sky-high. At Jet Tech Supplies, our machine vision software is built to help aerospace manufacturers like you catch defects, cut costs, and stay compliant—all without breaking a sweat. Ready to see how much you could save? Reach out to us today, and let’s get your quality control game soaring.